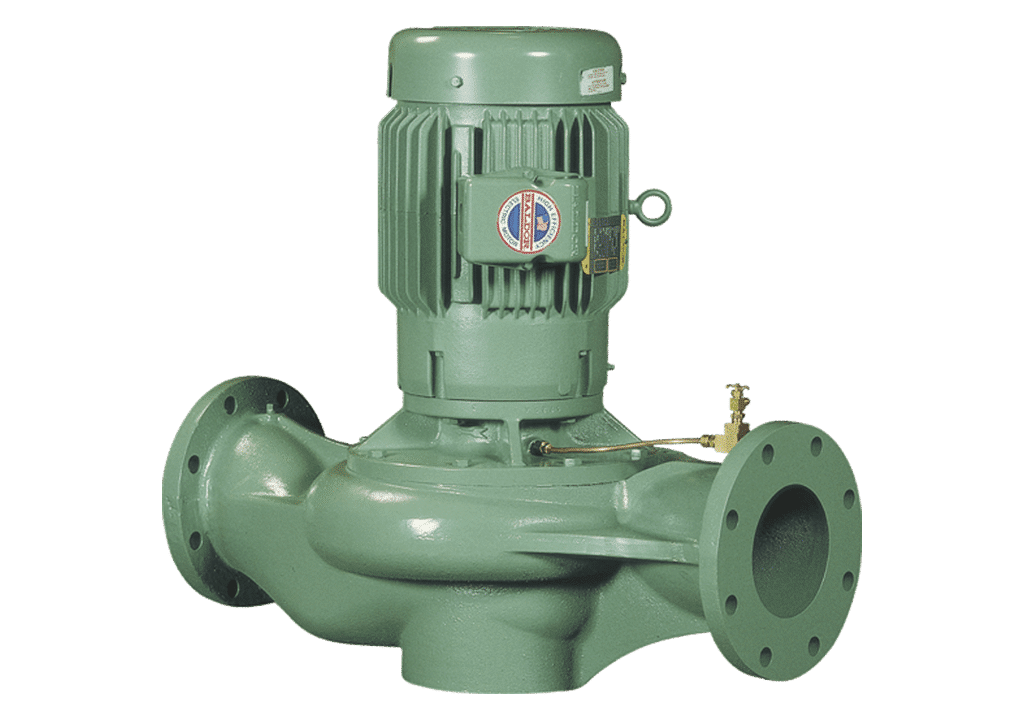

KV Series Vertical In-Line Pumps

Performance Data

Flow Range: 10 – 2,650 GPM

Head Range: 11′ – 385′

Temperature: 250°F (standard), 300°F (optional)

Working Pressure: 175 PSIG, 300 PSIG (optional)

HP: ¾ – 60

Sizes: 1 ½”- 8″

Features

- The vertical in-line design allows for ease of installation and maintenance, while maintaining a very small footprint that does not require isolation pads

- Closed coupled design provides improved alignment and increased seal life

- The axial load is hydraulically balanced to increase bearing life, improve pump efficiencies, and lower NPSH requirements

- The recirculating line flushes seal faces and extends seal life

Applications

- LoadMatch®Systems

- Hot Water Heating Systems

- Closed Cooling Circuits

- Air Conditioning Systems

- Hydronic Heating & Cooling

- Water/Glycol concentrations up to 50%

- Solar / Geothermal

Models & Related Documents

KV1506D

Flow: 10 – 191 GPM; Head: 2′ – 165′

KV1507D

Flow: 8 – 225 GPM; Head: 3′ – 228′

KV1509

Flow: 11 – 325 GPM; Head: 4′ – 385′

KV2006D

Flow: 14 – 290 GPM; Head: 2′ – 153′

KV2007D

Flow: 13 – 425 GPM; Head: 4′ – 227′

KV2009D

Flow: 14 – 380 GPM; Head: 5′ – 382′

KV2011

Flow: 15 – 210 GPM; Head: 6′ – 141′

KV3006D

Flow: 21 – 400 GPM; Head: 3′ – 147′

KV3007D

Flow: 29 – 900 GPM; Head: 2′ – 228′

KV3009D

Flow: 19 – 575 GPM; Head: 4′ – 359′

KV3011D

Flow: 26 – 400 GPM; Head: 8′ – 137′

KV3013D

Flow: 29 – 500 GPM; Head: 2′ – 179′

KV4007D

Flow: 43 – 1275 GPM; Head: 2′ – 222′

KV4009D

Flow: 43 – 1250 GPM; Head: 3′ – 339′

KV4011D

Flow: 52 – 795 GPM; Head: 4′ – 127′

KV4013D

Flow: 46 – 660 GPM; Head: 4′ – 176′

KV5007D

Flow: 53 – 1640 GPM; Head: 3′ – 212′

KV6007D

Flow: 200 – 1950 GPM; Head: 3′ – 195′

KV6009D

Flow: 75 – 1175 GPM; Head: 3′ – 83′

KV6011D

Flow: 95 – 1400 GPM; Head: 3 – 126′

KV6013D

Flow: 110 – 1700 GPM; Head: 7′ – 175′

KV8011D

Flow: 160 – 2400 GPM; Head: 5′ – 127′

KV8013D

Flow: 180 – 2650 GPM; Head: 3′ – 168′

Taco Comfort Solutions

Service & Support