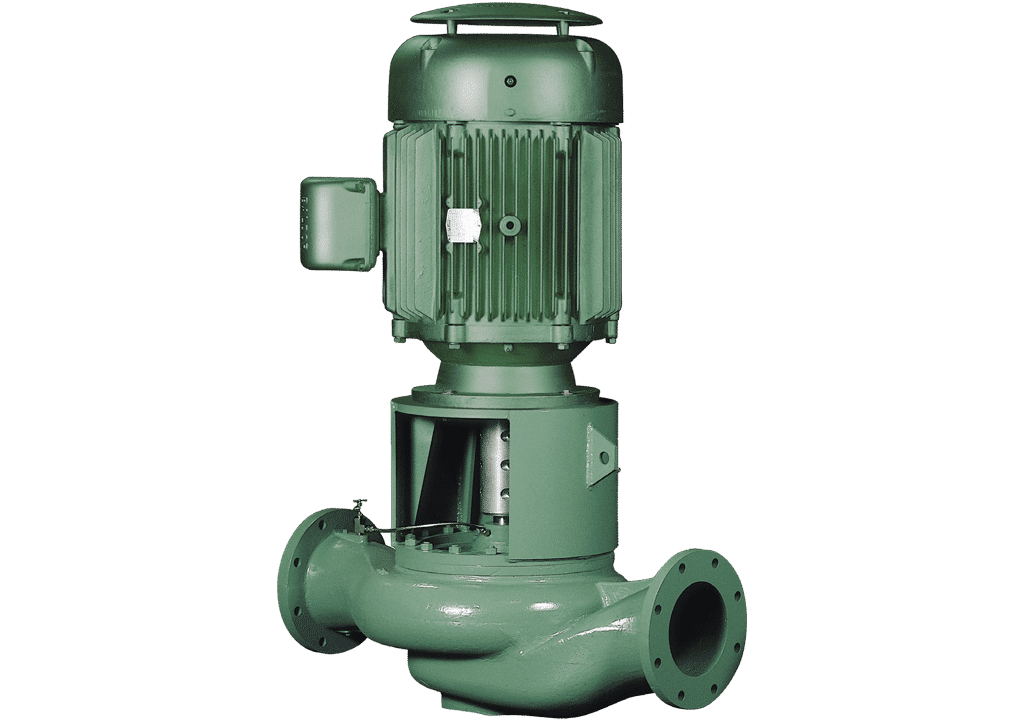

KS Series Vertical Split-Coupled In-Line Pumps

Performance Data

Flow Range: 40 – 12,500 GPM

Head Range: 10′ – 380′

Working Pressure: 175 PSIG Standard, 300 PSIG Optional

Temperature: 250°F Standard, 300°F Optional

HP: ¾ – 600

Sizes: 1 ½” – 14″

Features

- The vertical in-line design allows for ease of installation and maintenance, while maintaining a very small footprint that does not require isolation pads

- The split coupler design permits changing of the seal without disturbing the motor or the piping

- The axial load is hydraulically balanced to increase bearing life, improve pump efficiencies, and lower NPSH requirements

- The recirculating line flushes seal faces and extends seal life

Applications

- LoadMatch® System

- HVAC

- Industrial Applications

- Pressure Boosting

- Cooling Towers

- Domestic Water Services—flows up to 12,000 GPM

Models & Related Documents

KS1013

Flow: 232 – 3520 GPM; Head: 18′ – 152′

KS1016

Flow: 400 – 5400 GPM; Head: 22′ – 253′

KS1213B

Flow: 527 – 8000 GPM; Head: 9′ – 185′

KS1217

Flow: 800 – 10000 GPM; Head: 15 – 319′

KS1415B

Flow: 950 – 12784 GPM; Head: 4′ – 261′

KS1506D

Flow: 10 – 191 GPM; Head: 2′ – 165′

KS1507D

Flow: 8 – 225 GPM; Head: 3′ – 228′

KS1509

Flow: 11 – 325 GPM; Head: 4′ – 385′

KS2006D

Flow: 14 – 290 GPM; Head: 2′ – 153′

KS2007D

Flow: 13 – 425 GPM; Head: 4′ – 227′

KS2009D

Flow: 14 – 380 GPM; Head: 5′ – 382′

KS2011

Flow: 15 – 210 GPM; Head: 6′ – 141′

KS3006D

Flow: 21 – 400 GPM; Head: 3′ – 147′

KS3007D

Flow: 29 – 900 GPM; Head: 2′ – 228′

KS3009D

Flow: 19 – 575 GPM; Head: 4′ – 359′

KS3011D

Flow: 26 – 400 GPM; Head: 8′ – 137′

KS3013D

Flow: 29 – 500 GPM; Head: 2′ – 179′

KS4007D

Flow: 43 – 1275 GPM; Head: 2′ – 222′

KS4009D

Flow: 43 – 1250 GPM; Head: 3′ – 339′

KS4011D

Flow: 52 – 795 GPM; Head: 4′ – 127′

KS4013D

Flow: 46 – 660 GPM; Head: 4′ – 176′

KS5007D

Flow: 53 – 1640 GPM; Head: 3′ – 212′

KS6007D

Flow: 200 – 1950 GPM; Head: 3′ – 195′

KS6009D

Flow: 75 – 1175 GPM; Head: 3′ – 83′

KS6011D

Flow: 95 – 1400 GPM; Head: 3′ – 126′

KS6013D

Flow: 110 – 1700 GPM; Head: 7′ – 175′

KS8011D

Flow: 160 – 2400 GPM; Head: 5′ – 127′

KS8013D

Flow: 180 – 2650 GPM; Head: 3′ – 168′

KS8016

Flow: 250 – 3500 GPM; Head: 6′ – 282′

Taco Comfort Solutions

Service & Support