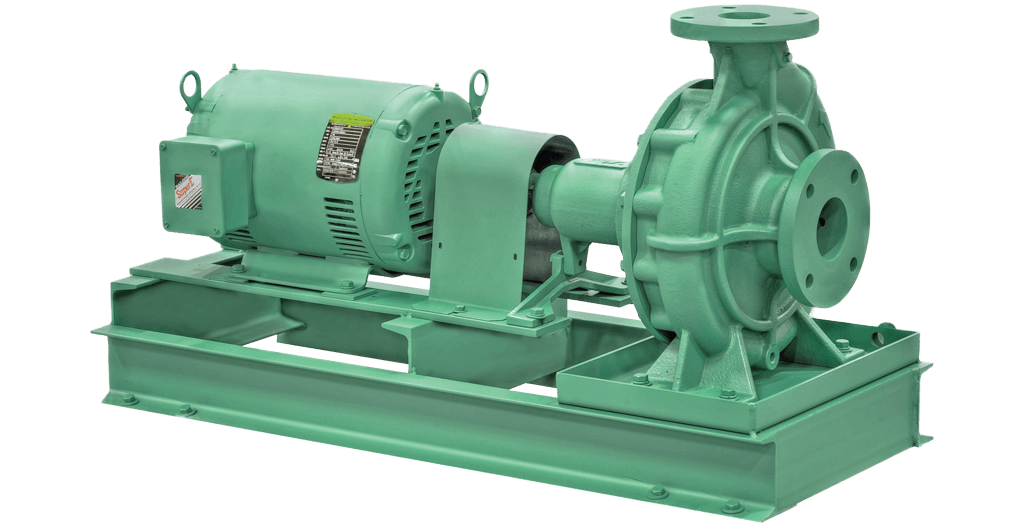

FI Series Base-Mounted End Suction Pumps

Performance Data

Flow Range: 20 – 4,800 GPM

Head Range (ft): 5 – 380′

HP: ½ – 200

RPM Range: 1160 – 3500

Sizes: 1.5″ – 8″

Features

- Motor Enclosure Type:

-

- TEFC or ODP

- Exclusive Dry Shaft Design Protects the Pump Shaft by Eliminating Contact Between the Shaft and Circulating Fluid

- A Fully Welded, Rigid Structural Steel Base, with Enclosed Ends and Open Grouting Area Reduces Vibration and Improves Alignment

- Sealed for Life Bearings and Unique Sealing System that Prevents the Migration of Water into the Bearing Frame

- Top Centerline Discharge Design Simplifies Piping Layouts, Reduces Piping Strain, and Makes the Pump Self-Venting

Applications

- Hot Water Heating Systems

- Closed Cooling Circuits

- Air Conditioning Systems

- Hydronic Heating & Cooling

- Water/Glycol concentrations up to 50%

- Solar / Geothermal

Models & Related Documents

FI1206D

Flow: 10 – 175 GPM; Head: 1′ – 167′

FI1207D

Flow: 8 – 240 GPM; Head: 5′ – 236′

FI1209C

Flow: 9 – 240 GPM; Head: 14′ – 390′

FI1506D

Flow: 15 – 280 GPM; Head: 1′ – 159′

FI1507D

Flow: 14 – 450 GPM; Head: 2′ – 235′

FI1509D

Flow: 14 – 325 GPM; Head: 5′ – 372′

FI1511B

Flow: 16 – 250 GPM; Head: 5′ – 139′

FI2007D

Flow: 15 – 475 GPM; Head: 5′ – 219′

FI2009D

Flow: 23 – 552 GPM; Head: 2′ – 390′

FI2506D

Flow: 20 – 400 GPM; Head: 3′ – 151′

FI2507D

Flow: 30 – 910 GPM; Head: 2′ – 223′

FI2509D

Flow: 34 – 851 GPM; Head: 5′ – 373′

FI2510C

Flow: 37 – 525 GPM; Head: 6′ – 104′

FI2511D

Flow: 35 – 530 GPM; Head: 4′ – 133′

FI2513D

Flow: 31 – 475 GPM; Head: 17′ – 181′

FI3007D

Flow: 35 – 1060 GPM; Head: 2′ – 229′

FI3009D

Flow: 48 – 1200 GPM; Head: 5′ – 327′

FI3011D

Flow: 49 – 790 GPM; Head:13′ – 128′

FI3013D

Flow: 59 – 900 GPM; Head: 4′ – 170′

FI4007D

Flow: 56 – 1700 GPM; Head: 3′ – 217′

FI4009D

Flow: 83 – 1200 GPM; Head: 4′ – 81′

FI4011C

Flow: 65 – 1014 GPM; Head: 13′ – 129′

FI4013D

Flow: 83 – 1259 GPM; Head: 2 – 174′

FI5007D

Flow: 79 – 2247 GPM; Head: 4′ – 183′

FI5009D

Flow: 91 – 1360 GPM; Head: 1′ – 82′

FI5011D

Flow: 99 – 1550 GPM; Head: 3′ – 124′

FI5013D

Flow: 119 – 1800 GPM; Head: 13′ – 171′

FI6009D

Flow: 150 – 2350 GPM; Head: 10′ – 87′

FI6011D

Flow: 161 – 2500 GPM; Head: 10′ – 122′

FI6013D

Flow: 171 – 2600 GPM; Head: 4′ – 181′

FI8013D

Flow: 290 – 4400 GPM; Head: 7′ – 183′

Taco Comfort Solutions

Service & Support