LOFLO® INJECTION PUMPING SYSTEM

Advanced Hydronic Radiant Heating and Cooling

The award-winning TACO LOFlo system sets a new standard in comfort, ease of design, and Green Building energy performance for small to large buildings.

Introduction to LOFlo®

Designers know that the demand for super efficient comfort systems grows each day. The industry has responded with a variety of new “Green” hydronic products and system concepts that yield dramatic benefits over the traditional and conventional airside designs of the past. The award-winning Taco LOFlo® Mixing Block (LMB) is one such product that sets a new standard for comfort, ease of design, and superior energy performance in small to large buildings. The LOFlo Mixing Block can easily be incorporated into heating and cooling systems for cost-effective results in a variety of areas. When employed in conjunction with Taco’s latest system approaches, outstanding benefits accrue to designers, installers, owners, and users alike.

The LOFlo® Concept

The LMB is a complete injection mixing station contained in a simple factory-assembled package that controls each individual zone at the lowest possible flow rate by maintaining the highest possible supply water temperatures in cooling and lowest possible supply water temperatures in heating. The LMB consists of a single cast header that functions as a hydraulic separator to which small circulators are attached – one for the primary system flow and the other an injection circulator that adjusts to precisely match the required load on a given zone. When installed within modern radiant systems ( wall, floor, or ceiling panels) or chilled beam systems (active or passive), only 2 pipes are needed. Flow rates are reduced since there are no control valves, balancing valves, or piping losses to overcome. The small, reliable circulators take the place of all of these components. The LMB automatically provides only the flow and temperature of water needed to satisfy the zone load at any given time.

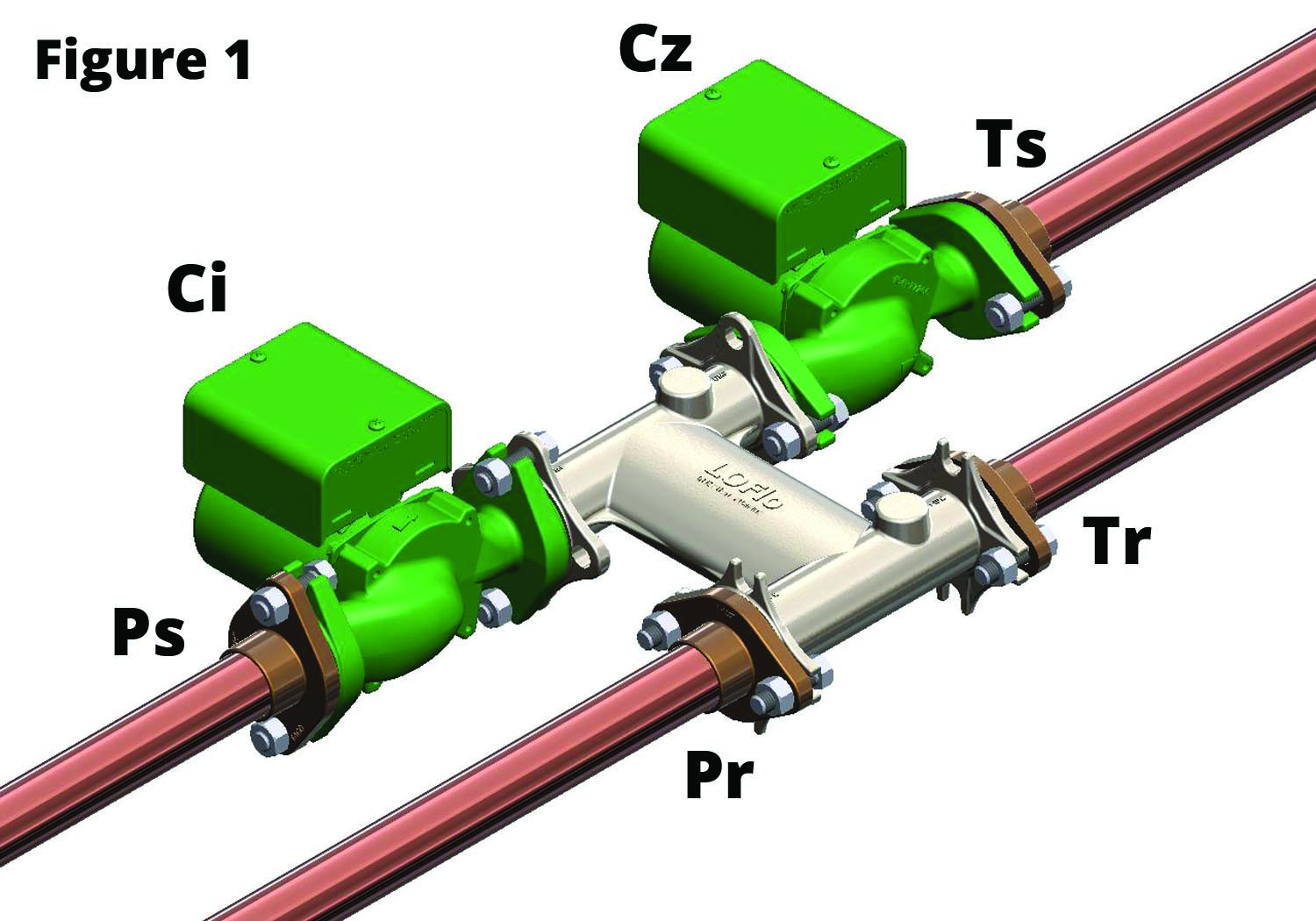

Figure 1 illustrates how the water supply from the primary circuit enters the LMB at Port (Ps). The return water from the secondary terminal loop enters the LMB at terminal (Tr). As the terminal unit calls for either heating or cooling, the Injection Circulator (Ci) varies in speed / flow to blend the two water temperatures to satisfy the needs of the zone. This blended supply water is sent to the terminal though Port (Ts) and primary return water exits the LMB at Port (Pr). A variety of sizes of LOFlo mixing blocks can handle flows up to 30 GPM, making them suitable for almost all installations.

Taco Comfort Solutions

Service & Support